-

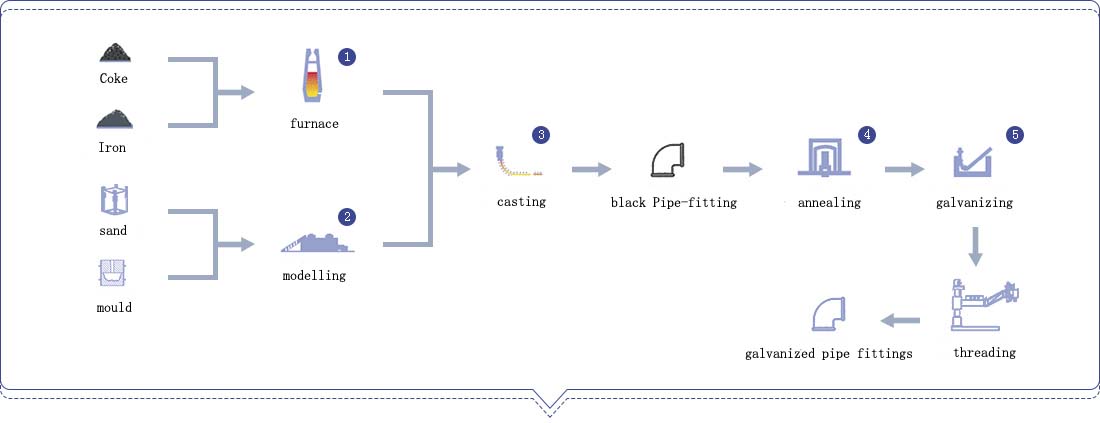

1

The raw materials of Malleable-iron steel includes iron, recycling steel. In order to acquire the malleable iron properties, good duclitity, the chemical composition should strict control within certain ranges. Typically, 3.5% of the carbon, 2.5% to 0.5% of silicon. Recently, the mature melting technology is mainly through either cupola, gas generator or electric furnace.

-

2

Mechanical modelling adopts the mature sand modelling method. Compared with the artificial modelling, mechanical modelling is more efficiency, and the casting part is neater.

-

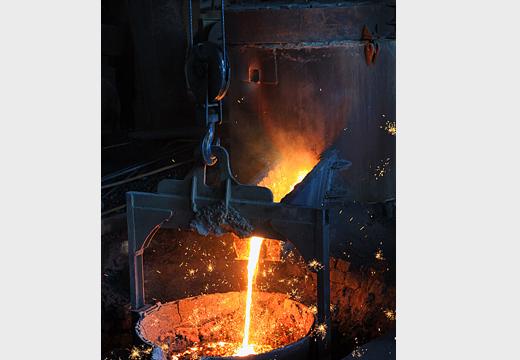

3

when the model has been built, pour molten iron into the cavity. After cooling and solidification of iron, the sand can be removed, and the semi-finished product was produced.

-

4

The semi-finished products must be putted into the annealing furnace in order to experience high temperature processing. Now annealing furnace is generally use electric or natural gas as a fuel source. When annealing treatment is completed, the product acquires its mechanical properties.

-

5

After to integer processing, the semi-finished products need to be dipped into hot zinc. Galvanized will greatly increase the corrosion resistance, thermal stability and hydrogen embrittlement of pipe-fittings.